|

|

|

||||

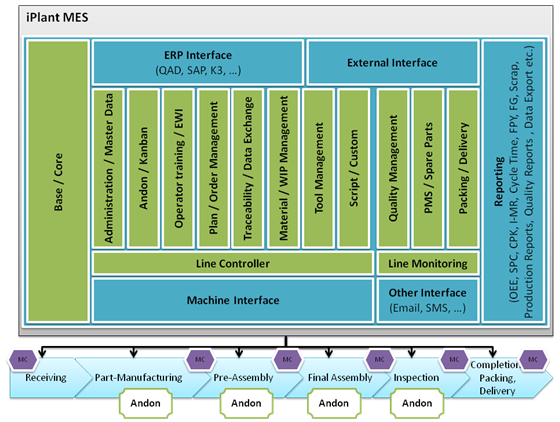

iPlant production line

MES is a new concept of production organization and management of the US manufacturing sector in the research and production management proposed in the 1990s, according to the International Joint MESA (MESA International) "MES through the transmission of information, under orders from the beginning to the single finished product throughout the production process to optimize the management of real-time events occurring plant, promptly react accordingly and report, and with current and accurate data on the corresponding guidance and treatment. "

According to preliminary needs to understand, combined with the general automobile enterprise information system planning, the project design to "plan and manufacturing" as the core, the radiation part of the procurement, storage and some areas of sales. This issue will not consider integration with PDM, PLM and other systems.

Industry internet have implemented production lines, such as machining (Rack, Bullnut, Housing, etc.), IPA, Sensor, Electronics (SMT, HSG ASSY, Coil, Power Module, Power Connector, ECU Assy etc.)Motor, Column, Shaft, Bracket, EPP and other fields have many years of experience in the implementation of MES, iPlant MES has been applied to many of the world-renowned key auto parts manufacturers, has been verified a lot of the actual production line,In this process, the understanding of the production line for EPS is gradually increased, has accumulated rich experience in the implementation. BMW also customers in the automotive electronics production line speed sensor aMES suppliers, the system has been running for many years, basically stable operation.

|

||

m.physics-andrea.com |