|

|

|

||||

ACC traceability system

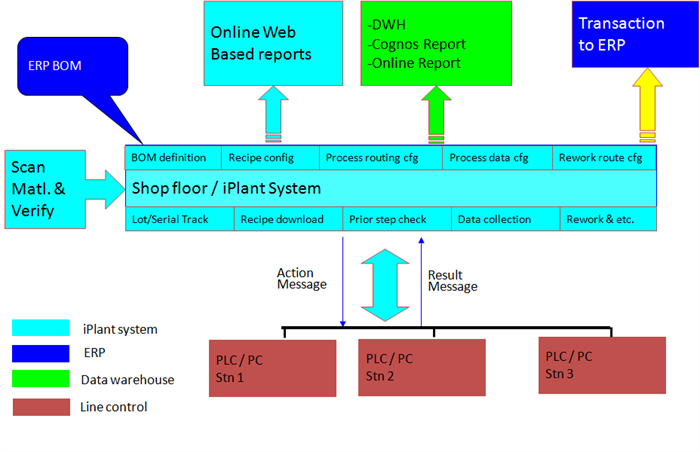

ACC is a systemic application to track and control the key Process data in Production Line; it provides Low cost solution to solve your real business issue for Production Line, such as mistake proof, trace your raw material, equipments, process data and operations;

ACC is to real-time communicate with production line/equipment and feeding the data to other upstream/functional system;ACC also provides a Real Time and on-line report to monitor and control your production line’s status, for instance, to display Cycle time, Day & Shift Summary status, 1st Pass Yield, Finished Goods status, SPC plot, Capacity of Machine, ACCurate Run Times for each operation, actual Audit Result, etc;Meanwhile, ACC application is easy to integrate with other ERP Systems, such as QAD MFG/PRO, SAP, or other 3rd-party systems; It is a system to link your production floor with your top floor applications;

ACC has established and developed a set of standard machine-ACC interface and ACC can communicate with variant control systems (like PLC – AllenBradley, Siemens, Bechhoff, Omron, Mitsubish, PC based system, CNC etc.) with high speed (non-OPC technology) to simplify control logic without cycle time loss;

ACC system is a pure Ethernet solution and it is easy for I.T. implementation and maintenance;

ACC system is flexible for different production lines and it helps for enterprise’s shop floor system standardizatio

Issue in production lines

Function

• Production line process modeling and routing proof

• Process parameter download to machine PLC

• Process data / test data collection

• Line performance data collection

• Rework control

• Serial number generation and label printing

• Boundary sample and station audit schedule enforcement

• Lot / Serial Traceability

• Packing and label printing

• SPC plot, SPC

• Data retention

• Live line status monitoring and Andon

• Reporting

•HMI Erorr proof

Technology Advantage

ü ERP system interface can be extended and integrated

|

||

m.physics-andrea.com |